Retrofitting has been one of the key elements for Isofred in the past 2021. The retrofitting of facilities allows for the improvement of various aspects of them, from adapting to an increase in production to reducing process consumption.

One of Spain’s leading seafood processing companies has joined the change for the better with the support of Isofred to service one of the most modern facilities with the highest production capacity in the sector. This centre, located near the town of Fraga, in Huesca, covers a surface area of 7,000 m2 with a refrigeration capacity of 6,000 m3.

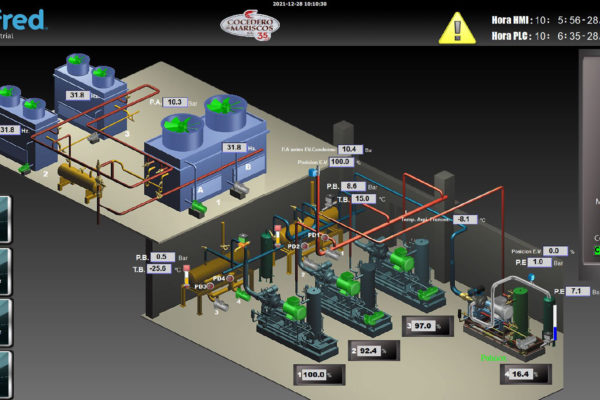

The old installations, which used to work with Freon, have been removed and replaced by more sustainable and efficient elements. Currently, the new equipment serves a spiral ultra-freezing tunnel that reaches -45ºC and a frozen food preservation chamber that works at -22ºC .

With this increase in the quality of its installations, the Cocedero joins the green energy and hydrofluorocarbon (HFC) phase-out trend that many companies have already started in view of the ban on these refrigerants in 2023.