ISOFRED makes a new installation and change of refrigerant at Aeropic.

Aeropic is a company in the meat sector specialising in the direct sale of poultry (quails, poussins and partridges, etc.).

In 2001, a large investment was made in modernisation and slaughter automation, making it one of the most modern slaughterhouses in Europe.

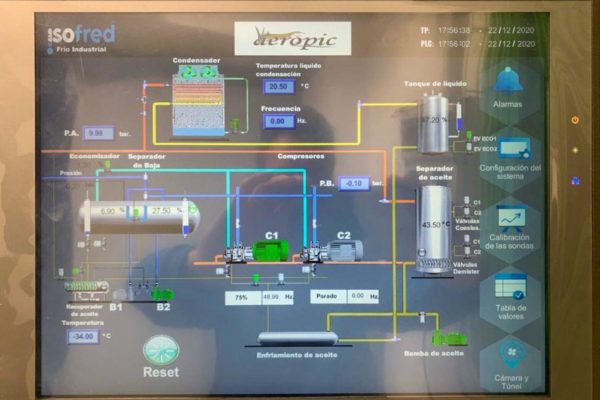

20 years later, Aeropic continues on the path to becoming a benchmark in meat production centres and renews its refrigeration installation, renovating its system for chambers with -20 ⁰C low temperature tunnels that can reach -30⁰C.

Isofred carried out the study, calculation and design of the project, our technical team advised the use of natural refrigerants, in this case ammonia (NH3) as it has a much higher efficiency than the previous fluorinated gases, it is tax-free, its recharge is cheaper and being natural does not affect the ozone layer, as its percentage of GWP and CO2 emission is 0, this entails the removal of hundreds of kilos of Freon (HFC gases).

The installation is headed by a compact Twin compact of one of our trusted Japanese company, Mayekawa model I125 pumped by TH WITT equipment, combined Open-Flash economizer, low oil separator and oil of our own production.

The main function of Isofred S.L. is to be an installer of industrial refrigeration, one of our most important competences is to advise and guide our customers, giving different options on the way to obtain the best result of their facilities and greater efficiency in them.